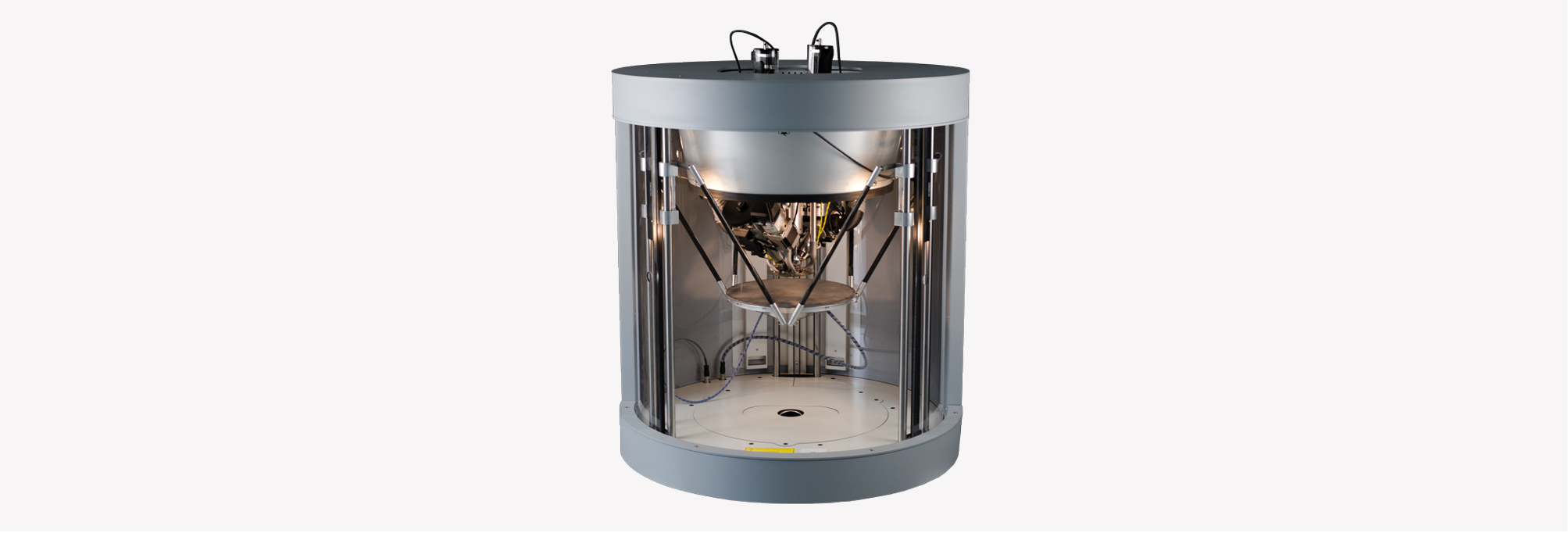

At the beginning of November 2023, Pollen AM welcomed Fabien Lanoue, PhD in materials chemistry, who will bring a valuable addition to Pollen AM, particularly within the Research & Development department. Fabien now holds the position of materials and process engineer in Pollen AM's laboratory, working directly on our 3D Pam printers and their designs.

This is an opportunity for Pollen AM to introduce you to Fabien, who works closely with the PAM process and plays an essential role within Pollen AM.

Could you introduce yourself, and describe your academic and/or professional background?

Fabien (FL) : Hello, my name is Fabien Lanoue, I'm from Nantes and I'm 26 years old. I'm a graduate of Toulouse INP-ENSIACET, where I studied Materials Engineering. This course significantly enriched my understanding of materials science and gave me solid skills in process engineering. It was during this period that my interest in additive manufacturing was confirmed, notably through various student projects and internships.

After obtaining my engineering diploma, I chose to continue on the path of research by starting a PhD at the CIRIMAT laboratory in Toulouse. My thesis focused on the development of additive manufacturing techniques to create composite parts combining metal and ceramics, a project that received joint support from CNES and Thales Alenia Space.

What led you to join Pollen AM?

FL : I chose Pollen AM for a number of key reasons. Firstly, I wanted to move into the private sector and get involved in a human-scale structure. Pollen AM, with a team of around ten people, ideally met this criterion. What's more, as a pioneer of 3D printing in France, the company stands out for its active commitment to innovation in additive manufacturing. Working at Pollen AM allows me to stay at the forefront of technology and contribute to major developments in this sector.

The areas of innovation explored by Pollen AM align with my research interests, particularly in the fields of new materials shaping, composite materials production and ceramic manufacturing process studies. A significant boost has recently been given to the latter, with the creation of a subsidiary in Belgium specializing in ceramics research.

Finally, having devoted a large part of my doctoral studies to laboratory research, I wanted to diversify my activities and broaden my professional horizons. Pollen AM offered me a position offering a variety of tasks, thus fulfilling my desire for professional development.

How did you integrate Pollen AM ?

FL : I joined Pollen AM at the beginning of November, where I received a particularly warm welcome. My induction began with training in the use of PAM systems via our online platform. This approach enabled me to quickly master the PAM systems. Shortly afterwards, I began to immerse myself in the Pollen AM laboratory team, where I gradually got my bearings and integrated efficiently.

Could you describe your typical day or week at Pollen, as well as the job you do?

FL : Describing a typical day at Pollen AM is a real challenge, because no two days are alike. The diversity of the projects I work on brings a lot of dynamism and stimulation to my daily routine. My activity is mainly centered around the laboratory, where I devote myself to developing new printing profiles. Since my arrival, I've worked on elastomers, filled polyamide and ABS. This work has involved developing printing profiles, improving the robustness of existing profiles, or adapting an existing profile to a different extruder configuration.

At the same time, I'm working on updating our e-learning platform, a tool designed to train our customers remotely. We plan to enrich this platform with content dedicated to our latest innovation, pam o2, to offer our users a complete and up-to-date resource.

Finally, I've been lucky enough to take part in trade shows to represent Pollen AM. This activity is particularly rewarding, as it gives me direct contact with the market and enables me to gather user needs and expectations.

What are the main challenges you have faced since you joined Pollen AM ?

FL : Since joining Pollen AM, I've been faced with several major challenges. My main challenge lies in bridging the gap between market needs and Pollen AM's current development projects. To achieve this, two key elements reinforce my action: the training I provide to Pollen AM clients and my active participation in trade shows. These two aspects provide me with a unique opportunity to observe current market trends and gather feedback from our users and potential future customers. The information gathered during these exchanges and observations is then used to guide our technical development plan. This translates into continuous improvement of our existing systems and informed choices concerning future developments of print profiles. This activity is both stimulating and rewarding. It gives me a clear and precise view of the current state of additive manufacturing, while giving me the means to take concrete action to prepare and shape its future.

What do you like best about your job?

FL : What I appreciate most about working at Pollen AM is the diversity of the projects I get to work on; no two days here are alike. Working at Pollen AM also gives me the feeling of actively contributing to innovation in the field of additive manufacturing, a passion close to my heart.

What's more, the fact that Pollen AM is a small company with around ten employees makes it much easier for us to communicate with each other and contributes to creating a particularly warm and friendly working environment, which I find very rewarding.

Do you have any particular interests or passions, whether related to additive manufacturing or not?

FL : Outside working hours, I'm very active and devote a lot of time to sport, particularly running, which I do regularly. Music is also a big part of my life; I take as much pleasure in listening to different genres as I do in playing an instrument. What's more, I'm passionate about board games and role-playing, which I find a great way of relaxing and sharing with friends and family.

Newsletter

sign up for updates

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2025 Pollen AM inc. All rights Reserved.

Français

Français