Plongeons dans les possibilités offertes par PAM

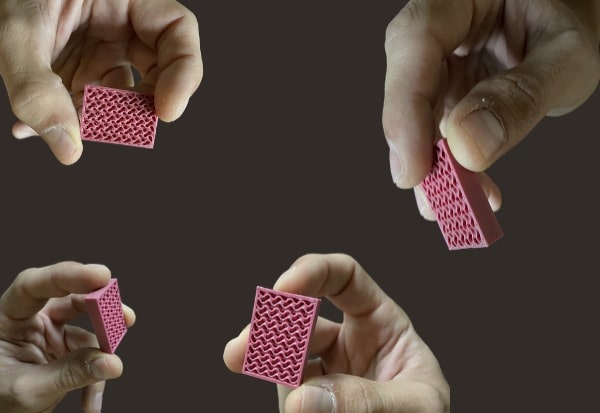

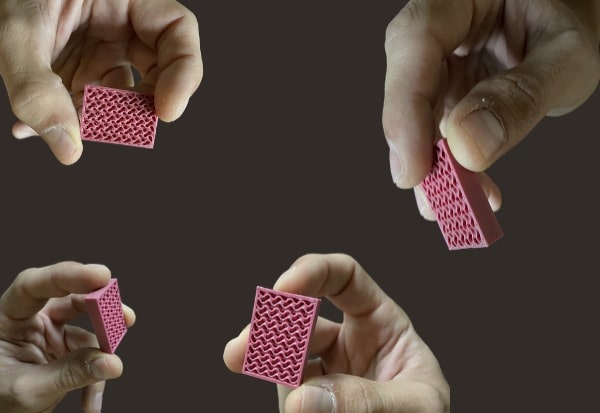

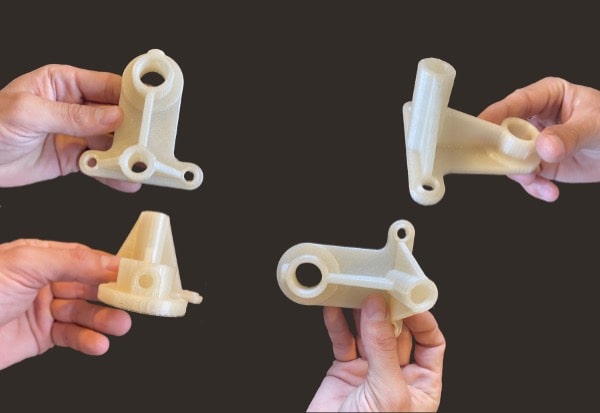

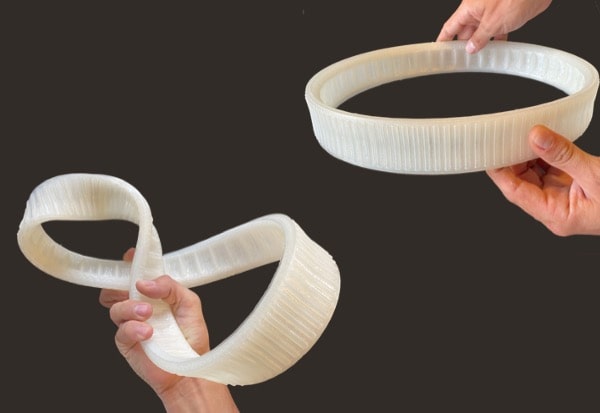

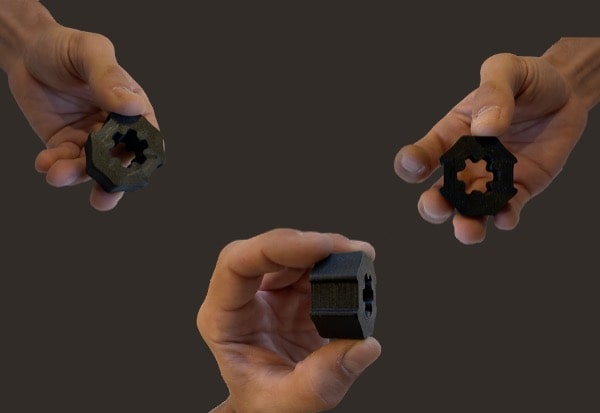

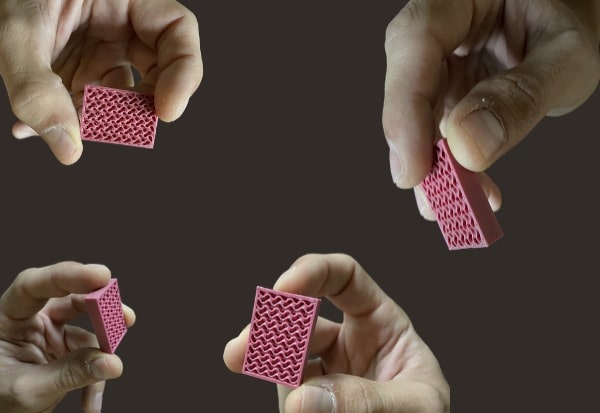

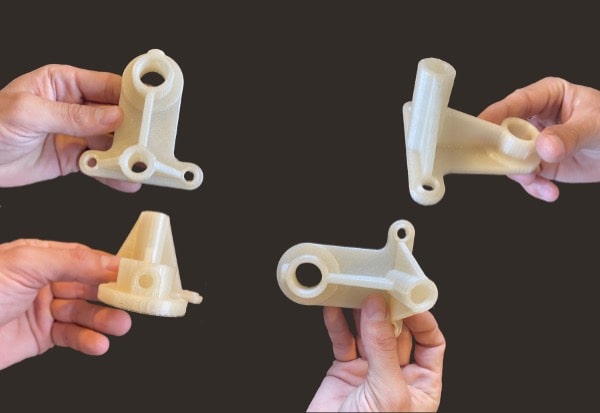

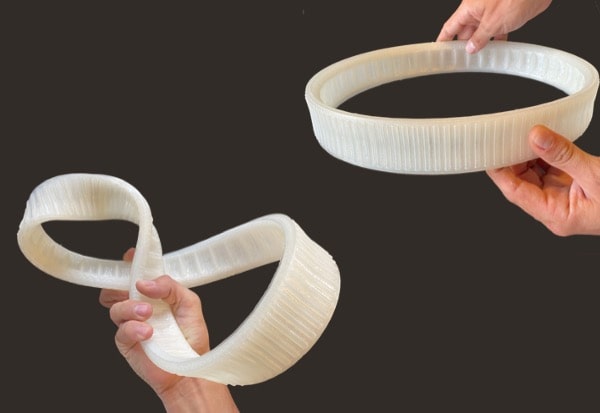

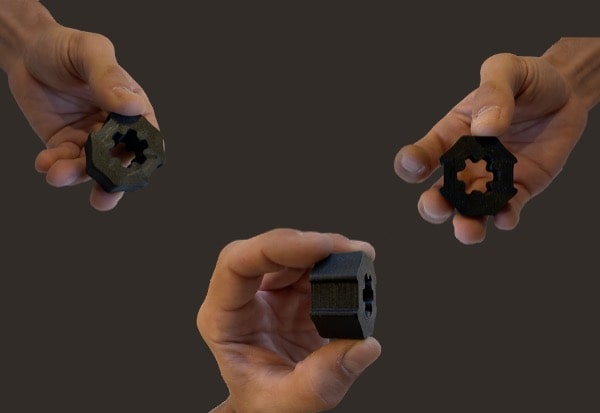

Des granulés à l'objet, la technologie PAM offre le processus le plus direct vers des pièces finales de haute performance.

Des granulés à l'objet, la technologie PAM offre le processus le plus direct vers des pièces finales de haute performance.

Nous ne partagerons jamais votre adresse électronique avec qui que ce soit.

Et vous pouvez vous désengager à tout moment. Nous vous le promettons.

© 2025 Pollen AM inc. All rights Reserved.