Let’s dive into the possibilities offered by PAM

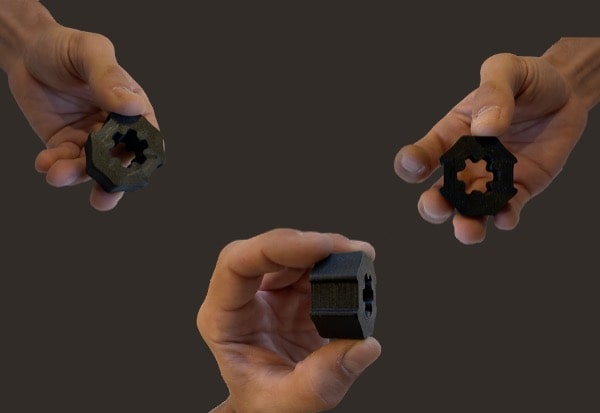

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2026 Pollen AM inc. All rights Reserved.