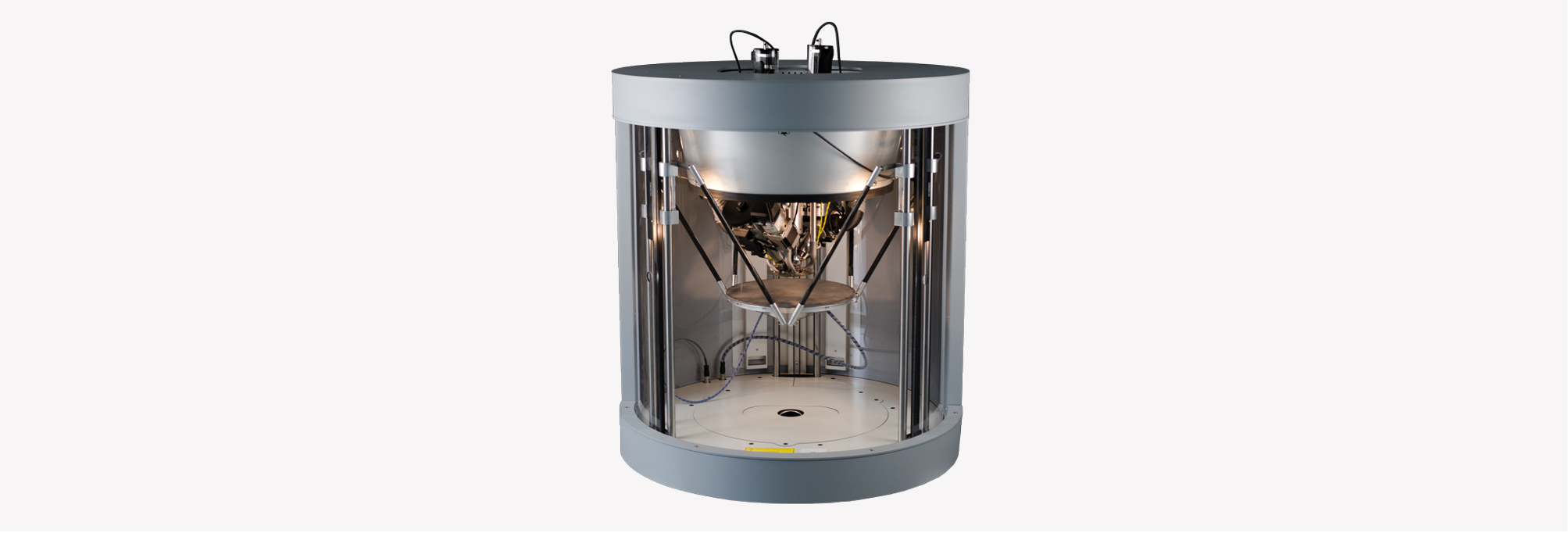

Pollen AM welcomed Maxime Carré in March 2022, during his internship, which was later transformed into a permanent contract. Maxime is now an Additive Manufacturing Engineer in Pollen AM's laboratory, working directly on our Pam 3D printers, under the supervision of the Laboratory Director.

This is the opportunity for Pollen AM to present you Maxime, who evolves very close to the PAM pellet additive manufacturing process.

Pollen AM: What are the reasons which pushed you to apply at Pollen AM?

Maxime (MC): What led me to apply at Pollen AM is mainly the desire to evolve in a human-sized SME, to be able to have a significant impact in the company, and to participate in innovative projects in a fast-growing sector.

Pollen AM: What formation did you follow? What is your professional background?

MC: I am an engineer with a specialization in mechanics oriented to materials, graduate of the University of Compiègne. I completed my fourth-year internship at the ICB-PMDM laboratory, which is attached to the University of Technology of Belfort-Montbéliard. There I was able to study SLS (Selective Laser Sintering) technology, which was my first experience in 3D printing. I wanted to continue in this sector for my end-of-study internship, which is why I joined Pollen AM.

“What led me to apply at Pollen AM is mainly the desire to evolve in a human-sized SME”

Pollen AM: Could you present your function in a few words?

MC: I am an additive manufacturing engineer. In other words, I oversee the follow-up of customer projects, the optimization of prints, and the maintenance of the machines.

Pollen AM: What is your typical workday? Your typical week?

MC: The first thing to do when you arrive in the morning is to analyze any parts that were printed overnight, and then restart the various 3D printers. The rest of the schedule can vary greatly depending on the day and week (I find this a good point). My recurring activities include analyzing the printability of the 3D models we receive and fine-tuning the systems for printing a new material or optimizing a print for a particular geometry, as well as preparing and maintaining the laboratory systems.

Pollen AM: What are the main challenges you face on a daily basis?

MC: Each new project presents its challenges, due to the wide variety of applications and materials we handle, whether it's a new material, a new test to improve the quality of our prints, etc. As Pam 3D printers are open machines that can accommodate a very large catalog of materials, we often receive requests for materials that are not used in 3D printing.

“Each new project presents its challenges, because of the wide variety of applications and materials we deal with”

Pollen AM: Do you have a particular project in mind that you worked on, and that made an impression on you?

MC: When I was still an intern at Pollen AM, I had the chance to participate in a complex "tri-material" project for an application in the automotive sector. The part to be printed was composed of a flexible portion, a rigid portion, and required water soluble supports. This project was very instructive and allowed me to appreciate the complexity of multi-material 3D printing applications. It was particularly rewarding to be able to produce this complex object with a printing process spanning over several days.

Pollen AM: What do you like the most in your work at Pollen AM?

MC: I really like the atmosphere at Pollen AM. There is a very good harmony within the team, and we are allowed to work in autonomy. Indeed, a dozen people are currently working at Pollen AM, so we have to be able to adapt, to respond in a more or less autonomous way to the different situations we may be confronted with. This is an aspect of the job that I find particularly rewarding. Moreover, the duties are extremely varied. One day I may find myself optimizing the parameters of a 3D printing process to obtain a part that best meets a customer's specifications; the next day I may be participating in a meeting with another customer for a completely different industry; and then I may go on to set up an internal tool to smooth out certain processes. Having such varied days allows you to never get bored and to constantly acquire new knowledge and skills.

Pollen AM: Do you have any passions or interests outside of work, related or not to 3D printing?

MC: Outside of work, I often listen to music. I also take part in role-playing sessions (or board games) in my free time. Besides, I pay particular attention to sustainable development issues, and I plan to set up a recycling process for 3D printing scraps in the next few months at Pollen AM.

“Having such varied days allows you to never get bored and to constantly acquire new knowledge and skills”

Pollen AM: How was your integration at Pollen AM?

MC: I had to train myself entirely on the machine, from scratch. So, I followed the Quick-Start training via the E-learning and knowledge-sharing platform, which allowed me to acquire a methodological, software, and technical toolbox. This theoretical training was completed simultaneously with a practical training directly on the Pam 3D printers.

Newsletter

sign up for updates

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2025 Pollen AM inc. All rights Reserved.

Français

Français