PEEK - Polyetheretherketone

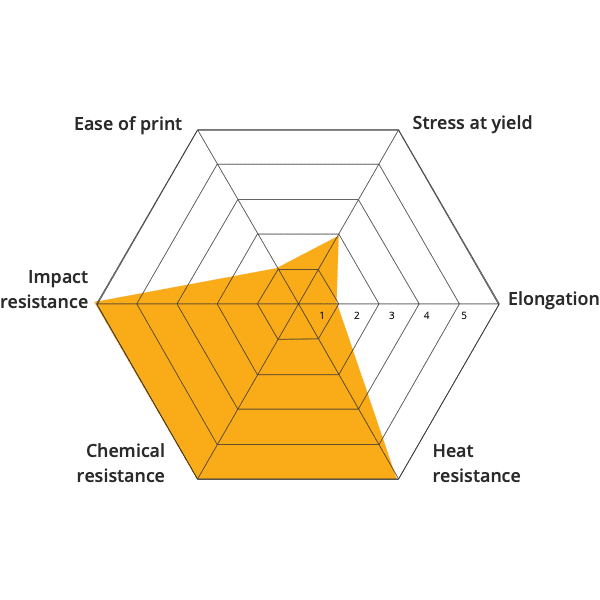

Polyetheretherketone (PEEK) is the most common and widely sold member of the polyaryletherketone family (PEAK). PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. It is highly resistant to thermal degradation, as well as to attack by both organic and aqueous environments.

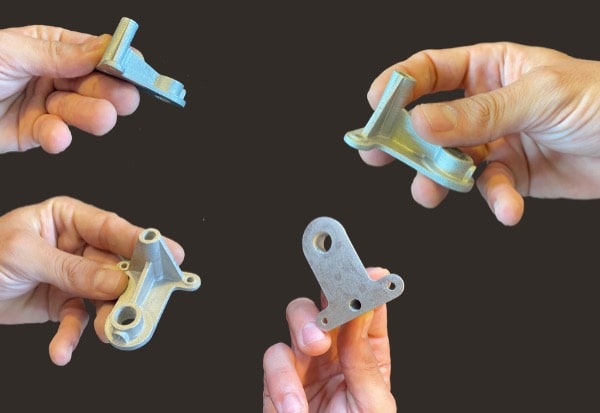

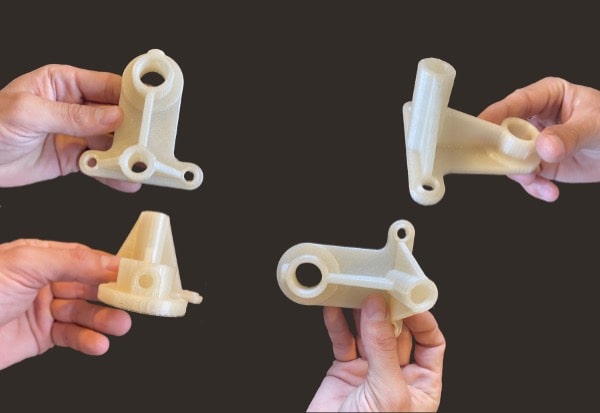

PEEK is mainly used in medical & healthcare applications, automotive electrical & electronic, aerospace applications, Oil & gas, etc.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 400 - 450°C |

| Buildplate substrate | HT buildplate |

| Builplate temperature | 130 - 150°C |

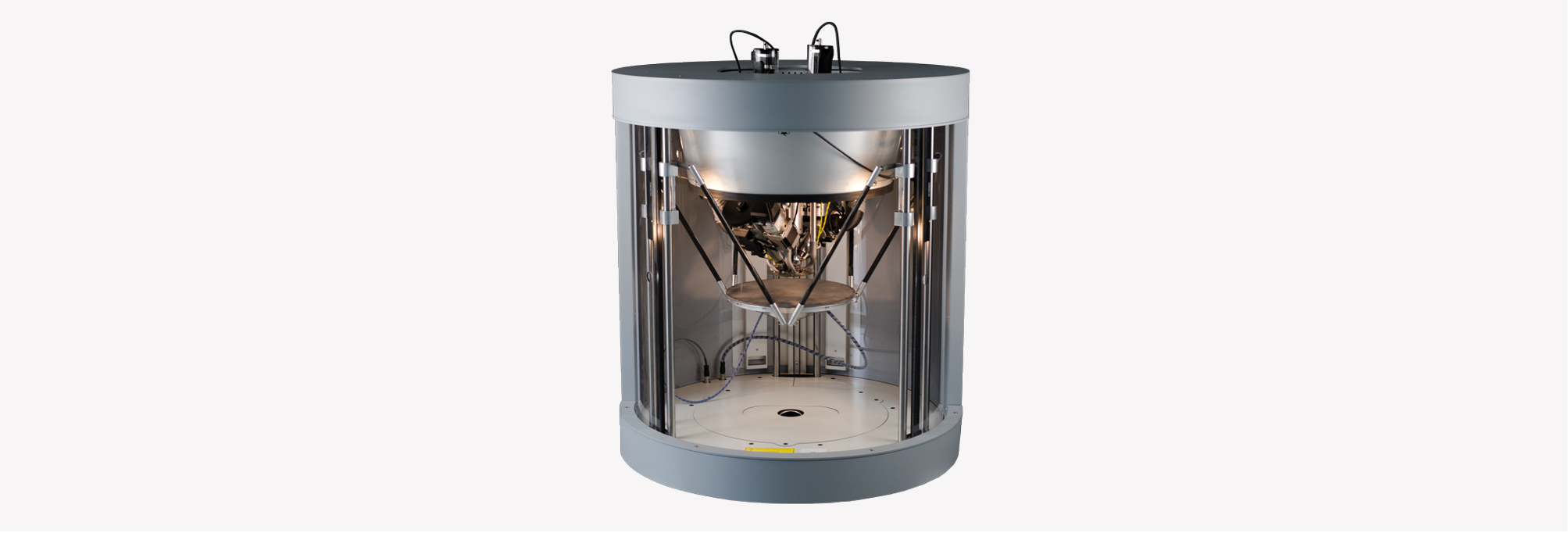

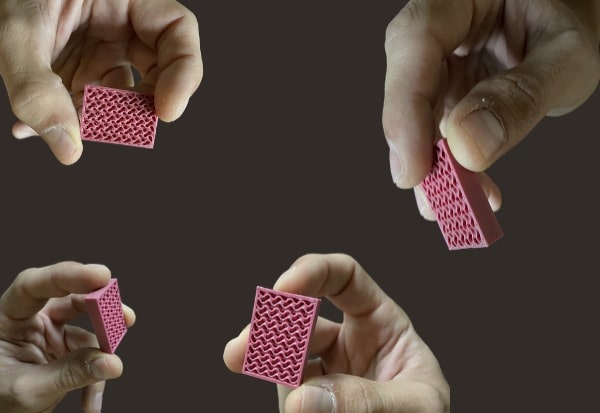

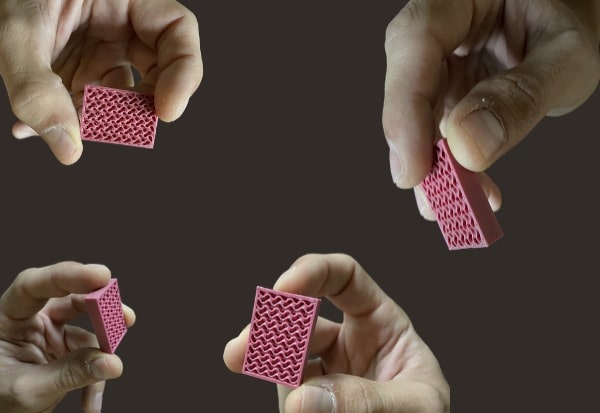

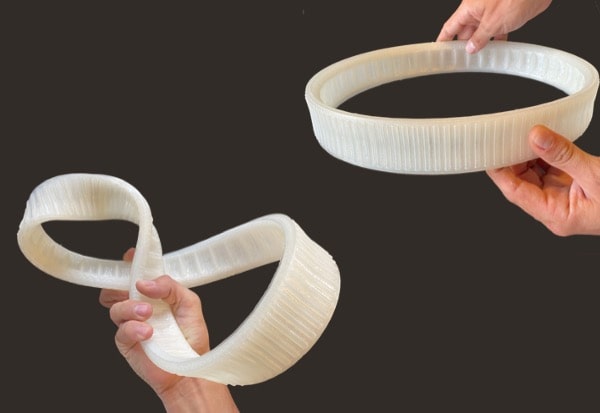

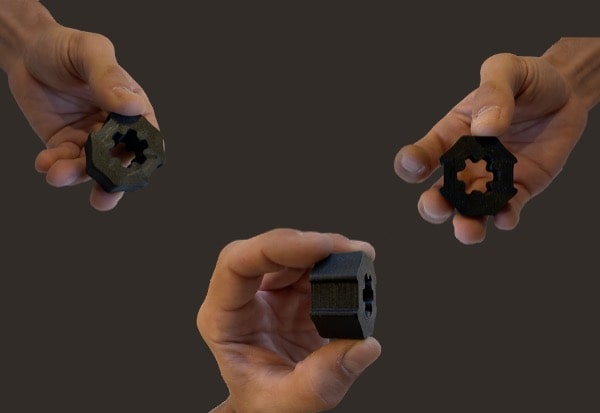

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français