PEI - Polyetherimide

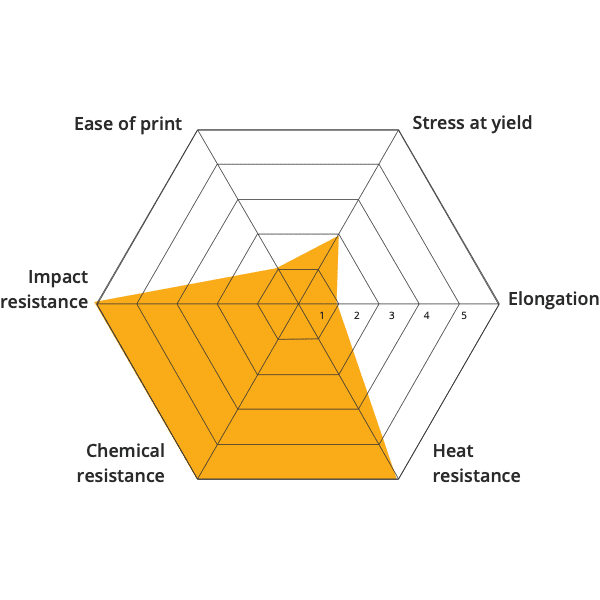

Polyetherimide (PEI) material is an amorphous thermoplastic part of polyimides thermoplastics. Unfilled PEI thermoplastic is translucent and amber in color with exceptional mechanical, thermal and electrical properties.

PEI plastic has similar characteristics to the polyarylsulphones (PSU, PPSU, PESU), while simultaneously offering significant advantages.

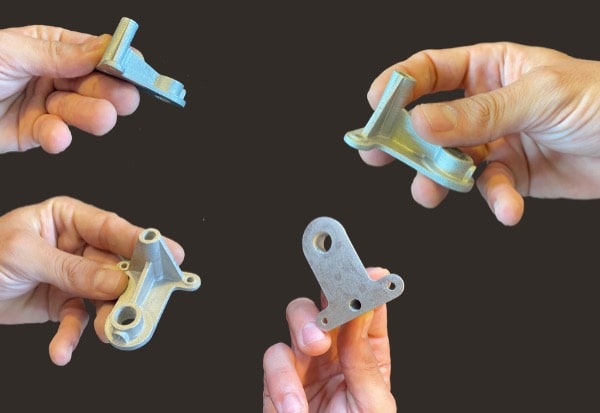

PEI is mainly used for electrical and electronic applications, household appliances, aircraft interior design, automotive (under engine hood, interior parts, etc.), medical, etc.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 350 - 420°C |

| Buildplate substrate | HT buildplate |

| Builplate temperature | 130 - 150°C |

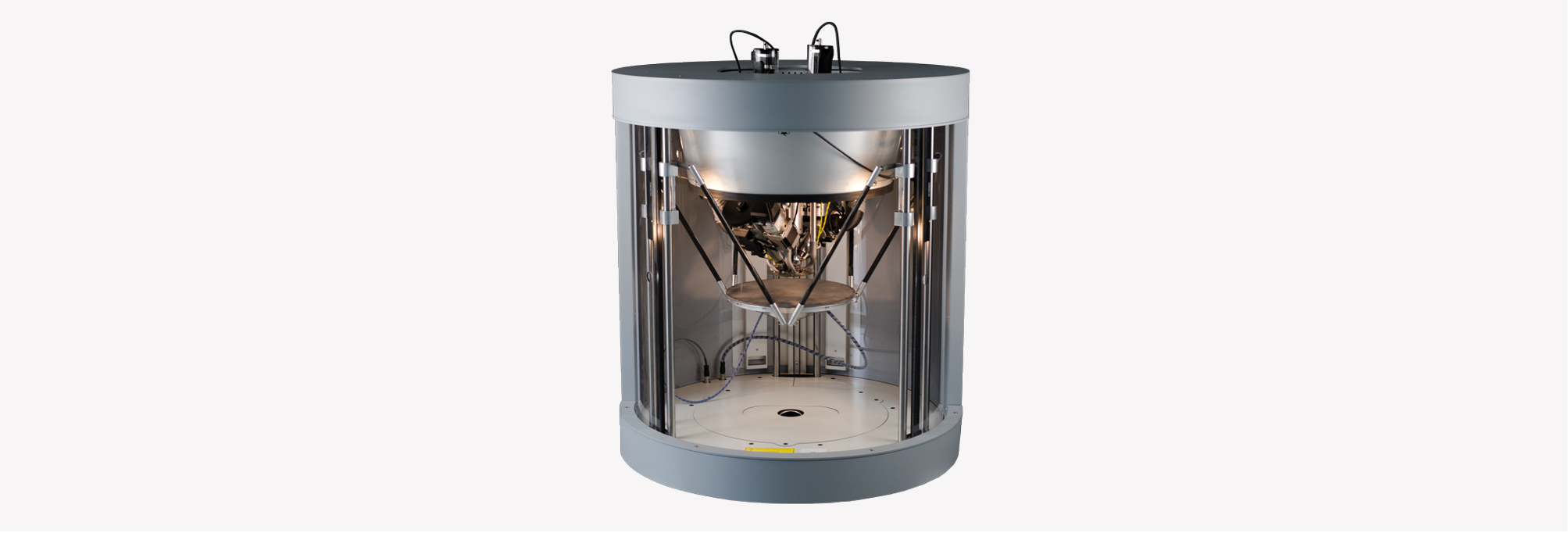

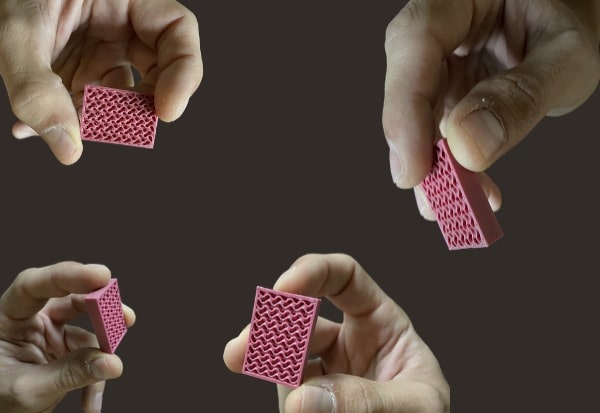

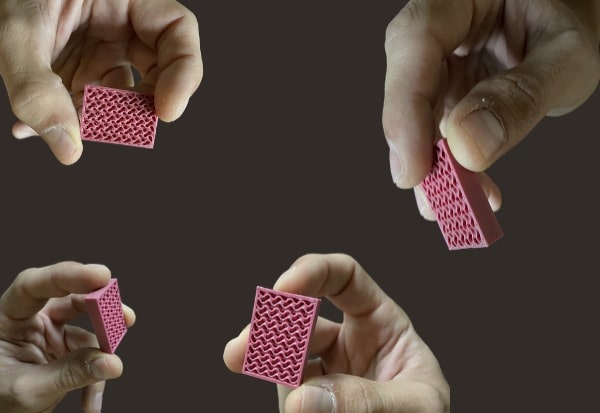

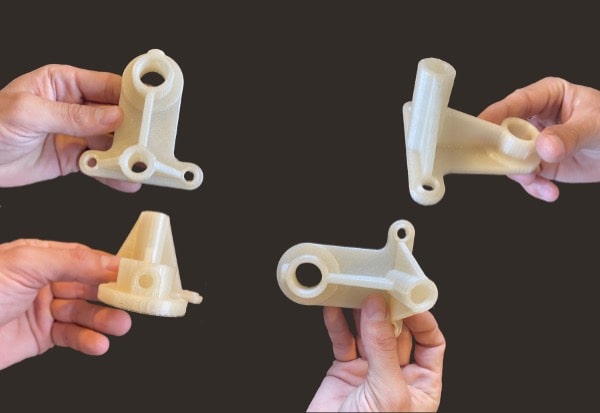

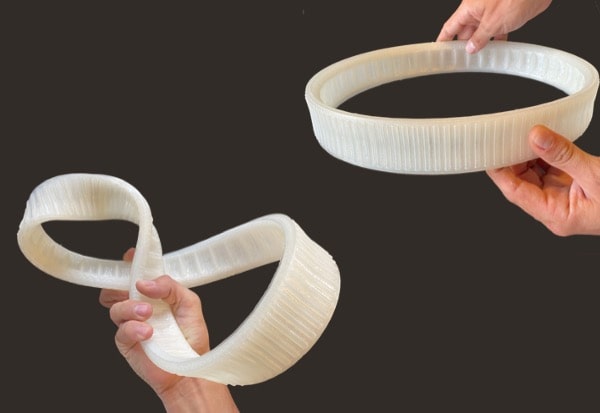

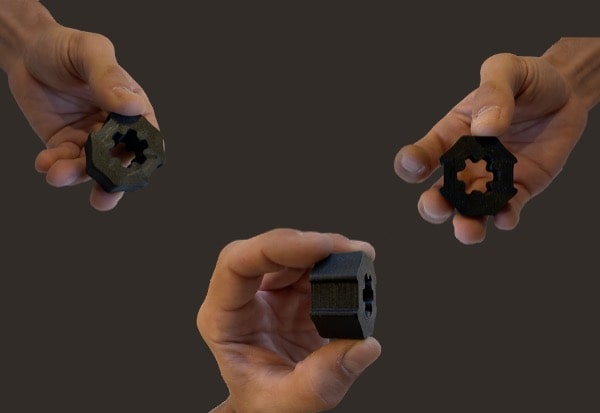

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français