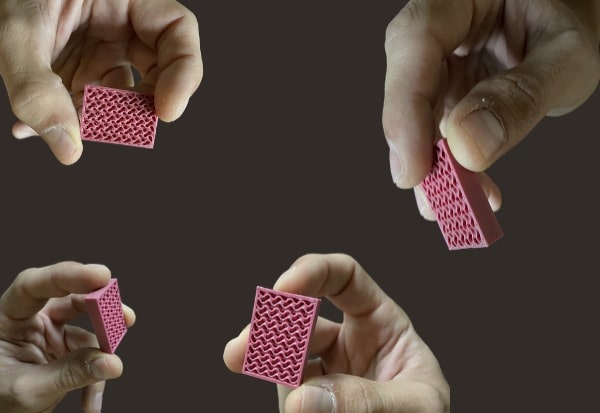

HPP - High Performance Polyester

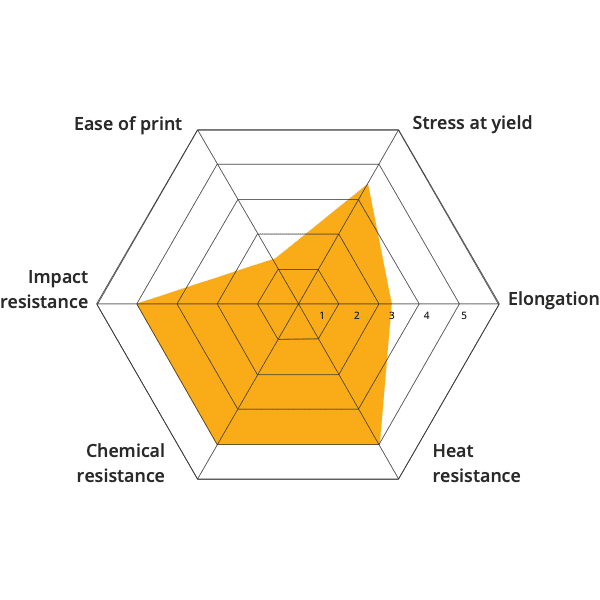

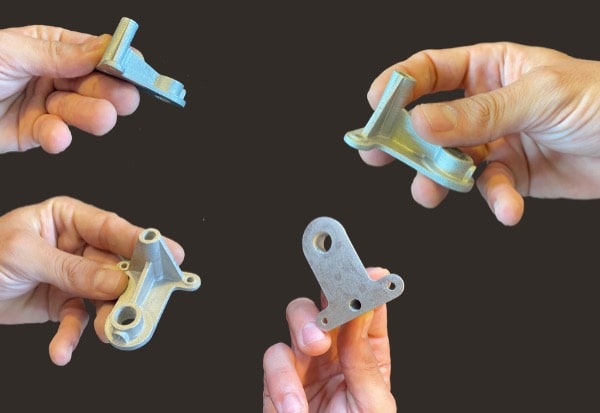

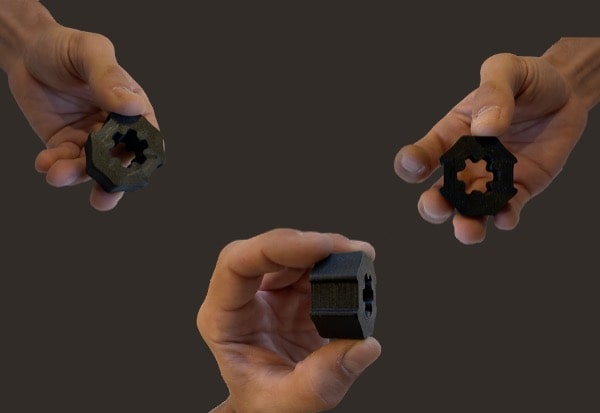

High Performance Polyester (HPP) offers strength and durability that provides an outstanding combination of mechanical properties and toughness. Chemical resistance and hydrolytic stability are improved compared to other copolyesters. Reinforced with glass is a good candidate for( mechanical and electrical uses at elevated temperatures.

HPP is neutral in taste, food, heat resistant, unbreakable, it is a good alternative to the PC. It is often used for the production of housewares, appliances, electronics and healthcare.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 270 - 300°C |

| Buildplate substrate | Micro-perforated buildplate |

| Builplate temperature | 70 - 90°C |

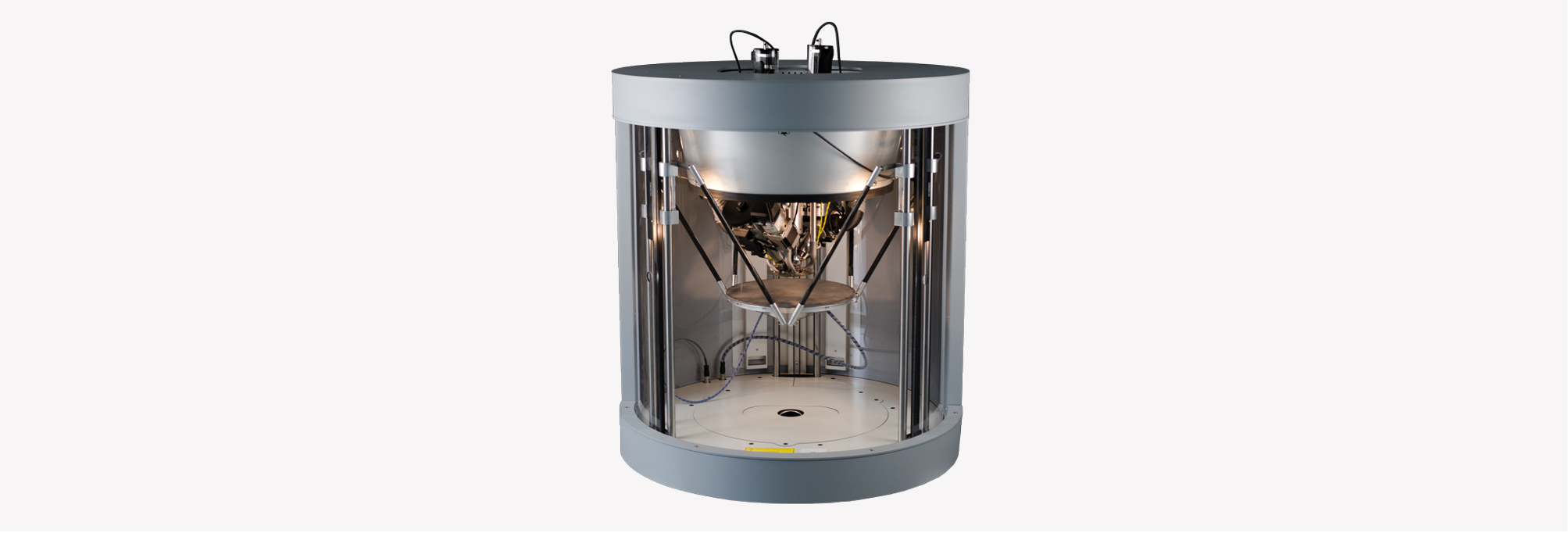

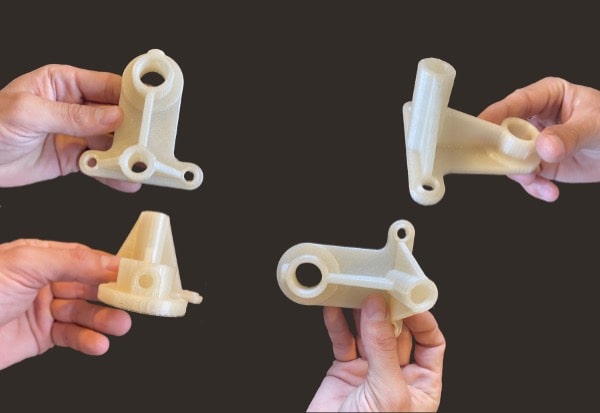

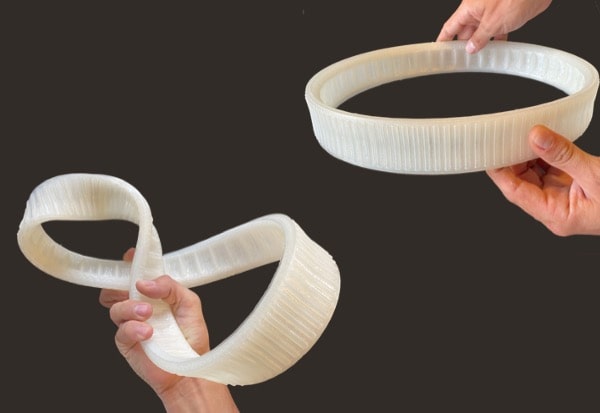

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français