POM - Polyoxymethylene

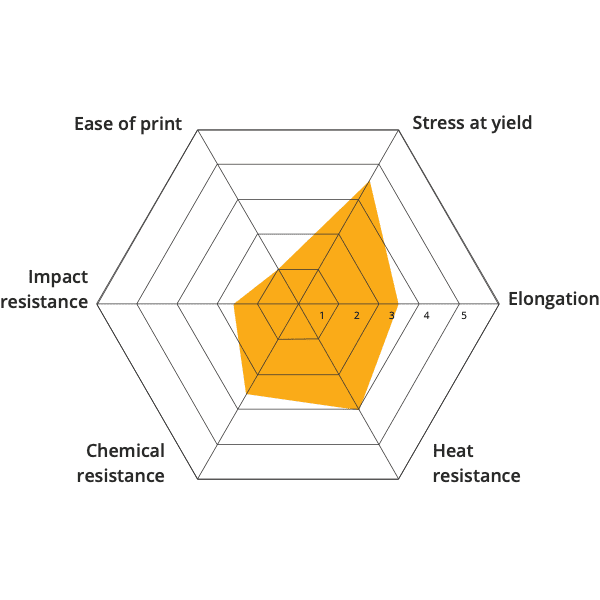

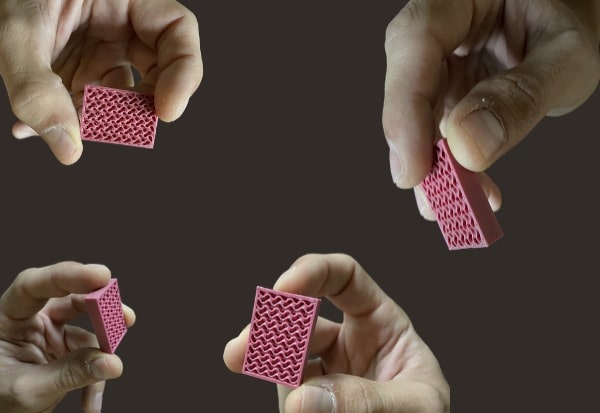

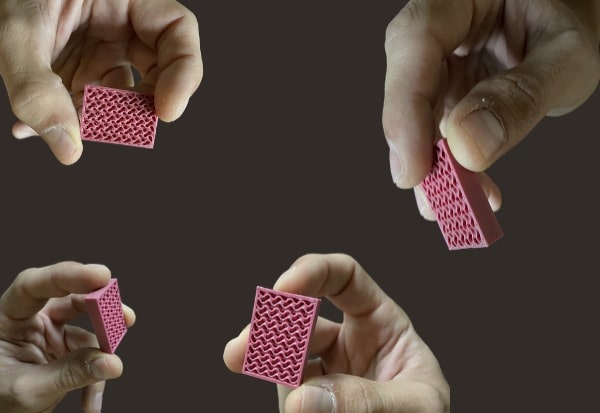

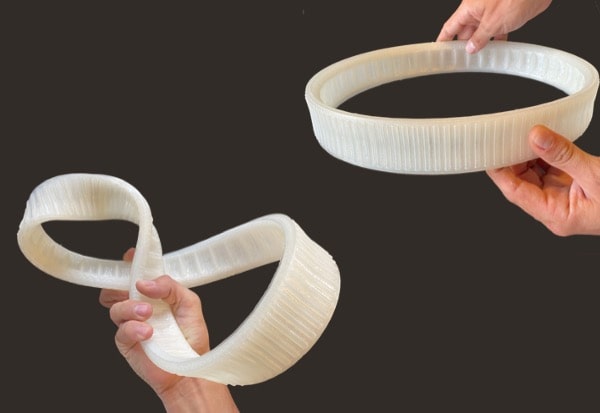

Polyoxymethylene (POM) can withstand high mechanical constrains. POM is rigid, creep resistant and resists various stresses without deforming. It has a low-friction coefficient, which gives it a good resistance to wear.

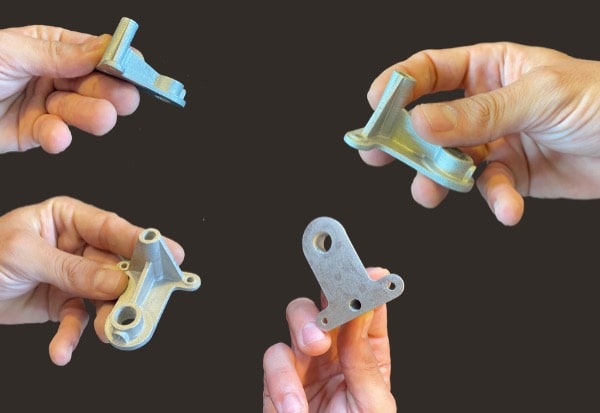

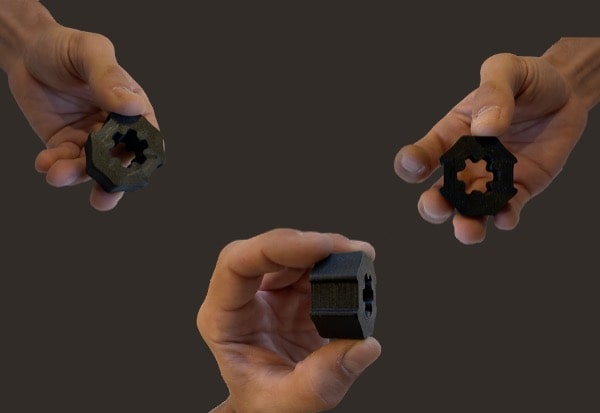

POM is commonly used for gears, shock components, friction components, electrical and electronic industry.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 180 - 230°C |

| Buildplate substrate | Micro-perforated buildplate |

| Builplate temperature | 80 - 110°C |

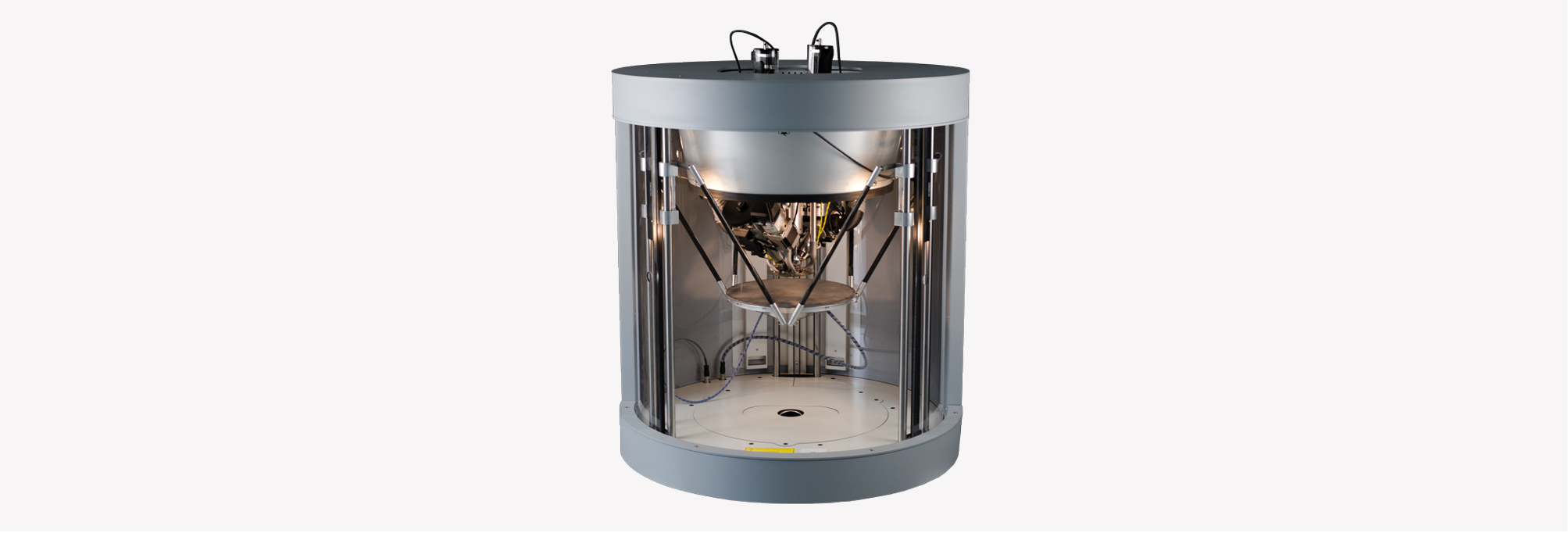

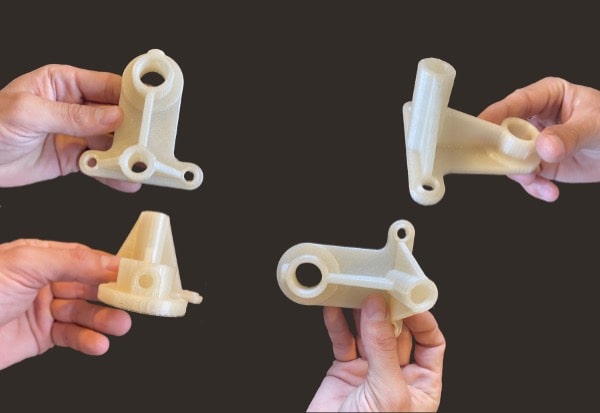

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français