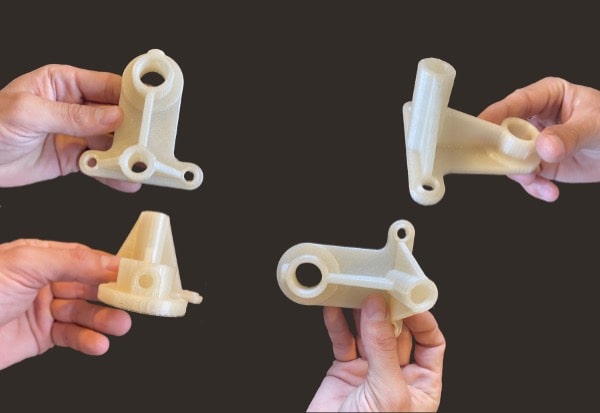

PC - Polycarbonate

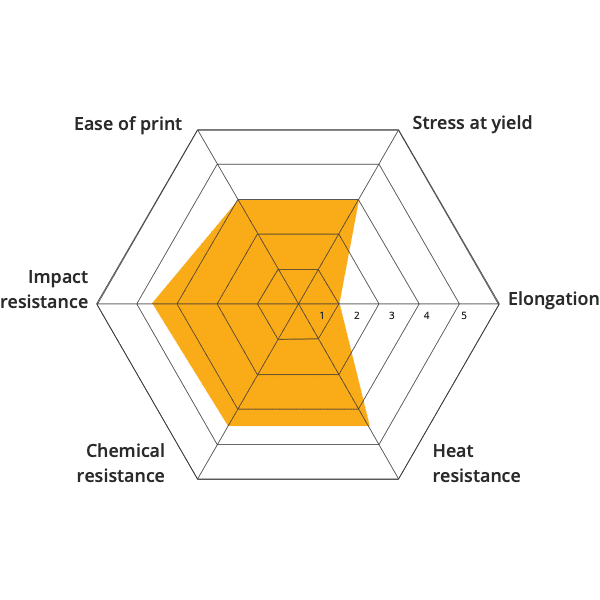

Polycarbonate (PC is a polymer with high transparency and is very resistant to impacts. This material is very rigid and has excellent mechanical properties that are characterized by low expansion and low heat distortion.

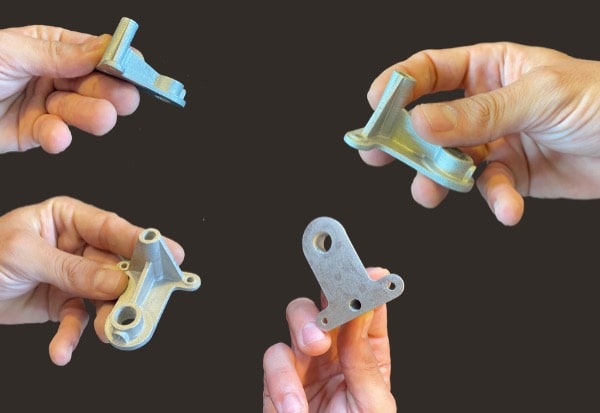

Due to these properties, PC is mainly used for electrical and telecommunications applications, for example in the automotive industry.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 280 - 320°C |

| Buildplate substrate | PC film | Micro-perforated buildplate |

| Builplate temperature | 80 - 120°C |

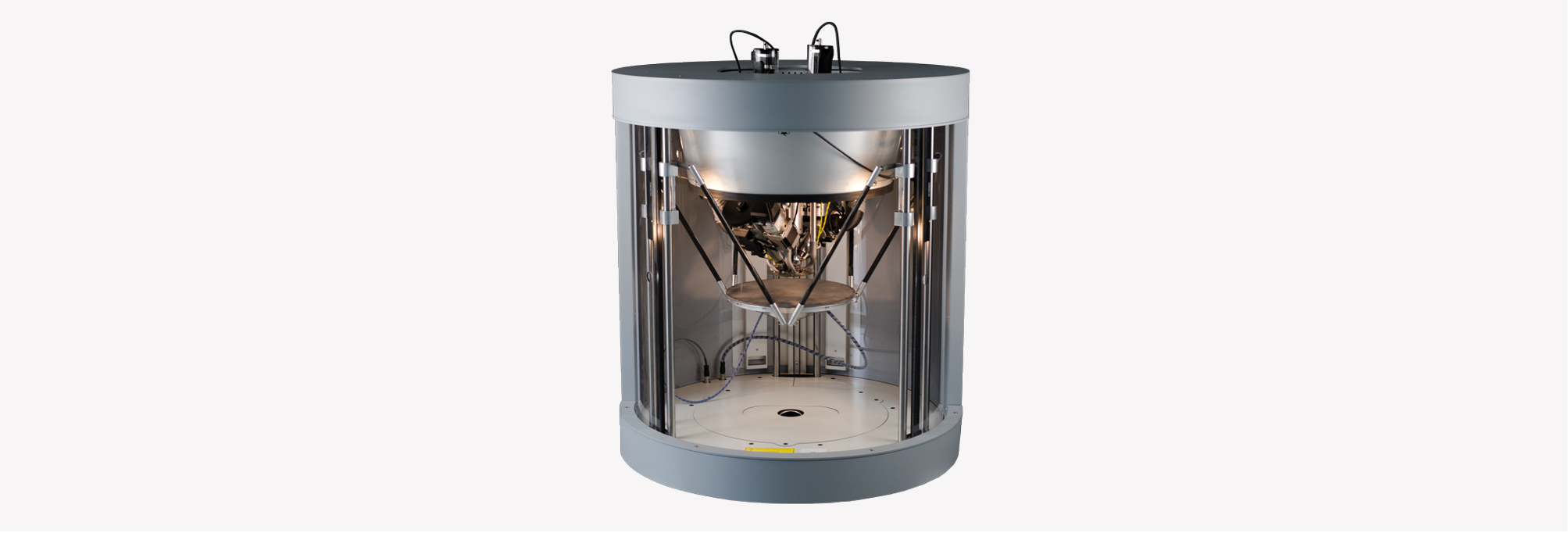

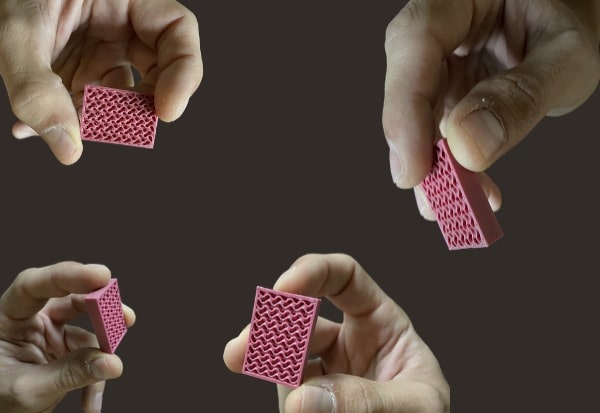

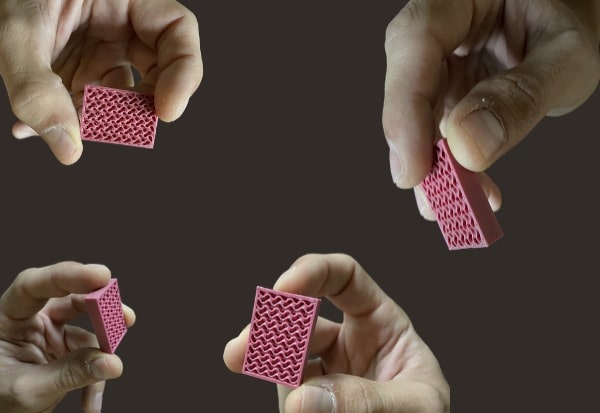

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français